How AI at the Edge is Reinventing Manufacturing Quality

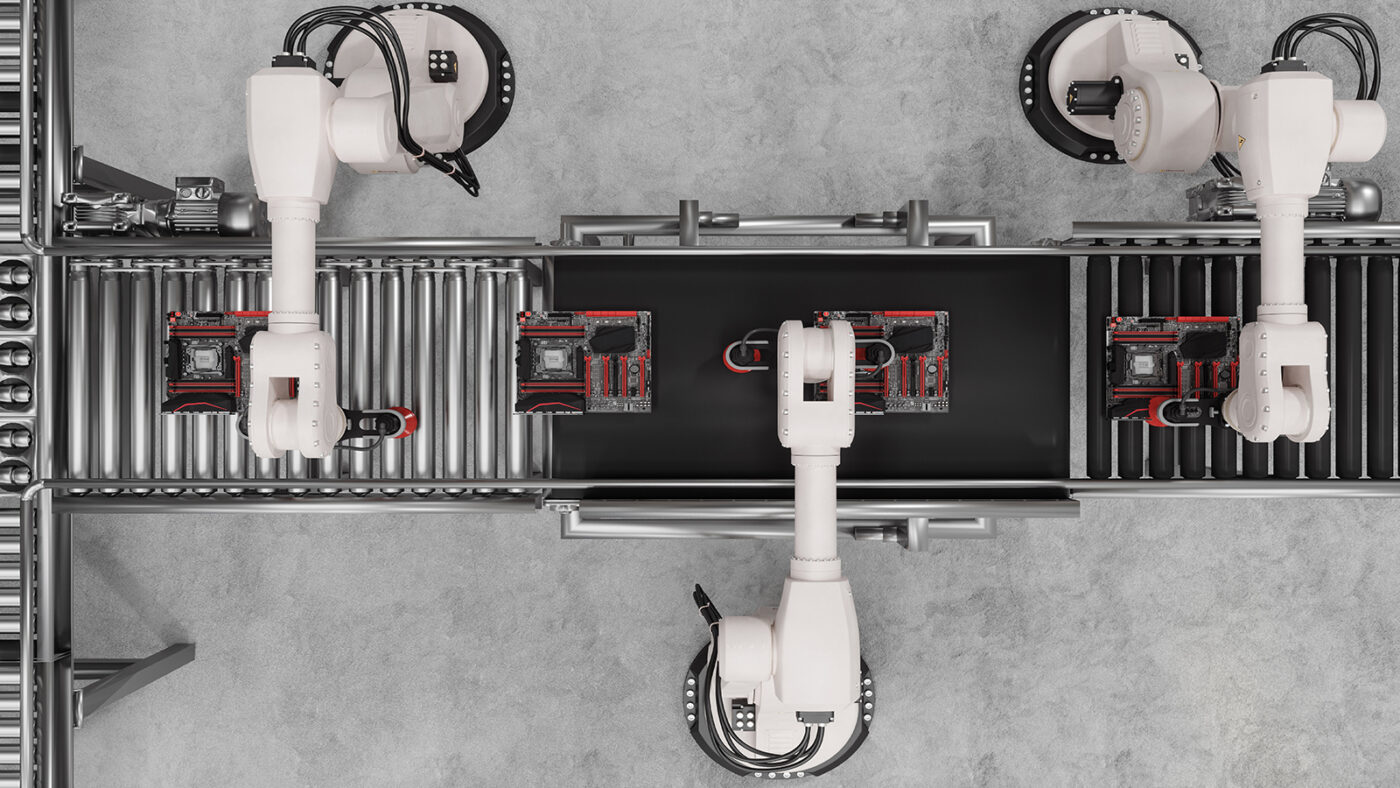

Imagine a factory floor where every component is built to perfection, where anomalies are caught before they become problems, and where machines get smarter with every product they make. This reality is made possible by AI-powered quality control and intelligent automation. What was once a competitive edge is fast becoming a baseline requirement for modern manufacturing.

In an era where efficiency, consistency, and cost control are critical, manufacturers are turning to AI and edge computing to revolutionize how quality is maintained. Companies like Siemens, in partnership with Arm, are at the forefront of this transformation.

Why Does Traditional Quality Control Not Always Work?

Traditional quality control relies heavily on manual inspections and post-production audits. This reactive model often catches defects too late, leading to waste, rework, and potential customer dissatisfaction. For global manufacturers operating at scale, even a small defect rate can snowball into millions in lost revenue and reputational damage.

What Does AI-driven Quality Control Do?

AI flips the traditional model by turning quality control from reactive to proactive. Machine Learning (ML) models analyze sensor data in real time, detecting anomalies during production, not after. These systems continuously learn, helping manufacturers fine-tune their processes and prevent defects before they happen.

Embedding AI at the edge places intelligence directly in the production environment, enabling manufacturers to respond instantly to deviations. Edge AI cameras, for example, monitor critical variables like temperature, humidity, vibration, and pressure. When a parameter drifts from the optimal range, alerts are triggered, and corrective actions are initiated.

This approach improves throughput, reduces waste, and enhances product consistency.

Siemens: A Leader in Smart Automation

Siemens exemplifies how AI-driven quality control is reshaping modern manufacturing, especially at the edge. At the heart of this transformation is the Armv9-based edge AI platform, a secure and energy-efficient foundation that enables real-time intelligence where data is generated. This platform empowers industrial innovators like Siemens to deploy powerful AI models directly on the factory floor, accelerating response times and reducing reliance on cloud connectivity.

Using Arm-based technology, Siemens has integrated generative AI into its production systems to predict and prevent failures in real time. These AI models anticipate defects in electronic components before they materialize, enabling dynamic recalibration of production settings. The result is precision manufacturing with minimal scrap—and a system that improves with every cycle.

As Herbert Taucher, VP Research and Predevelopment for IC and Electronics at Siemens AG, puts it:

“Siemens is committed to unlocking the power of AI in edge applications. The Armv9-based edge AI platform will help to extend our portfolio of highly secure, performant, and energy-efficient AI innovation to all our customers, across a range of industrial, smart infrastructure, and mobility applications.”

What’s the Business Case for AI-Enhanced Quality Control?

Large-scale deployments of AI-driven quality control have cut defect rates by as much as 90%. That means fewer product recalls, less rework, and millions saved, while consistently delivering high-quality products that boost customer satisfaction and reduce warranty claims.

Other business benefits include:

- Reduced Operational Costs: Less manual inspection means fewer labor hours spent on quality control tasks.

- Minimized Waste: Early defect detection helps catch issues before large batches are produced.

- Improved Safety and Compliance: AI helps ensure adherence to industry standards and safety protocols.

- Continuous Improvement: Feedback loops driven by machine learning allow processes to self-optimize over time.

Why Does Edge AI Matter for Quality Control?

Edge AI computing is crucial for real-time quality control. Rather than relying on cloud-based systems that introduce latency, edge AI allows for instantaneous decision-making on the factory floor. Energy-efficient, high-performance processors built on the Arm architecture are capable of handling complex AI workloads on-device and providing instant responses.

Whether retrofitting legacy systems or designing new smart facilities, integrating Arm-based edge AI solutions provides manufacturers with the responsiveness needed to stay competitive.

What is the Future of Quality Control?

Quality control is no longer just about inspection. It’s a continuous process involving prevention, prediction, and precision. AI-driven automation is moving from a competitive advantage to a manufacturing necessity.

For companies like Siemens, the integration of AI and edge computing is not just optimizing operations, it’s redefining what’s possible in manufacturing.

And with partners like Arm providing the computing foundation for scalable, secure edge AI, the future of flawless production is well within reach.

Key Takeaways

- AI is moving quality control from reactive to predictive: Manufacturers can now detect and correct anomalies during production, significantly reducing defects, waste, and rework.

- Edge computing is essential for real-time decision-making: Arm-based platforms enable low-latency AI processing directly on the factory floor, avoiding the delays of cloud-based systems.

- Partnerships like Siemens and Arm show real-world impact: By using Armv9-powered edge AI, Siemens has developed systems that forecast and prevent failures, driving smarter, more efficient manufacturing operations.

Frequently Asked Questions

How does edge AI improve quality control in manufacturing?

Edge AI enables real-time detection and correction of defects during production. By running AI models directly on devices like cameras and sensors, manufacturers can identify anomalies immediately, reduce waste, and ensure consistent quality, without latency from cloud processing.

What are the key benefits of using Arm-based platforms for AI-driven automation?

Arm’s energy-efficient, high-performance processors allow AI workloads to run directly at the edge. This powers intelligent quality control systems that are responsive, scalable, and secure, essential for modern factories that demand low latency and high reliability.

Can AI replace manual quality inspections entirely?

AI isn’t just replacing manual inspections, it’s redefining them. By shifting from reactive audits to proactive, continuous monitoring, AI significantly reduces the need for human intervention, cuts defect rates, and enables systems that improve over time through machine learning.

What results can manufacturers expect from deploying AI in quality control?

Large-scale deployments of AI-enhanced quality control have reported up to a 90% reduction in defects, lower operational costs, and improved product consistency. These outcomes translate into fewer recalls, increased customer satisfaction, and millions in annual savings.

Unlock the Power of Edge AI in Real-World IoT

Explore how AI at the edge is reshaping industries—from real-time decision-making to smarter, more efficient operations.

Any re-use permitted for informational and non-commercial or personal use only.