Edge AI in industrial automation: Why OEMs are moving to Arm

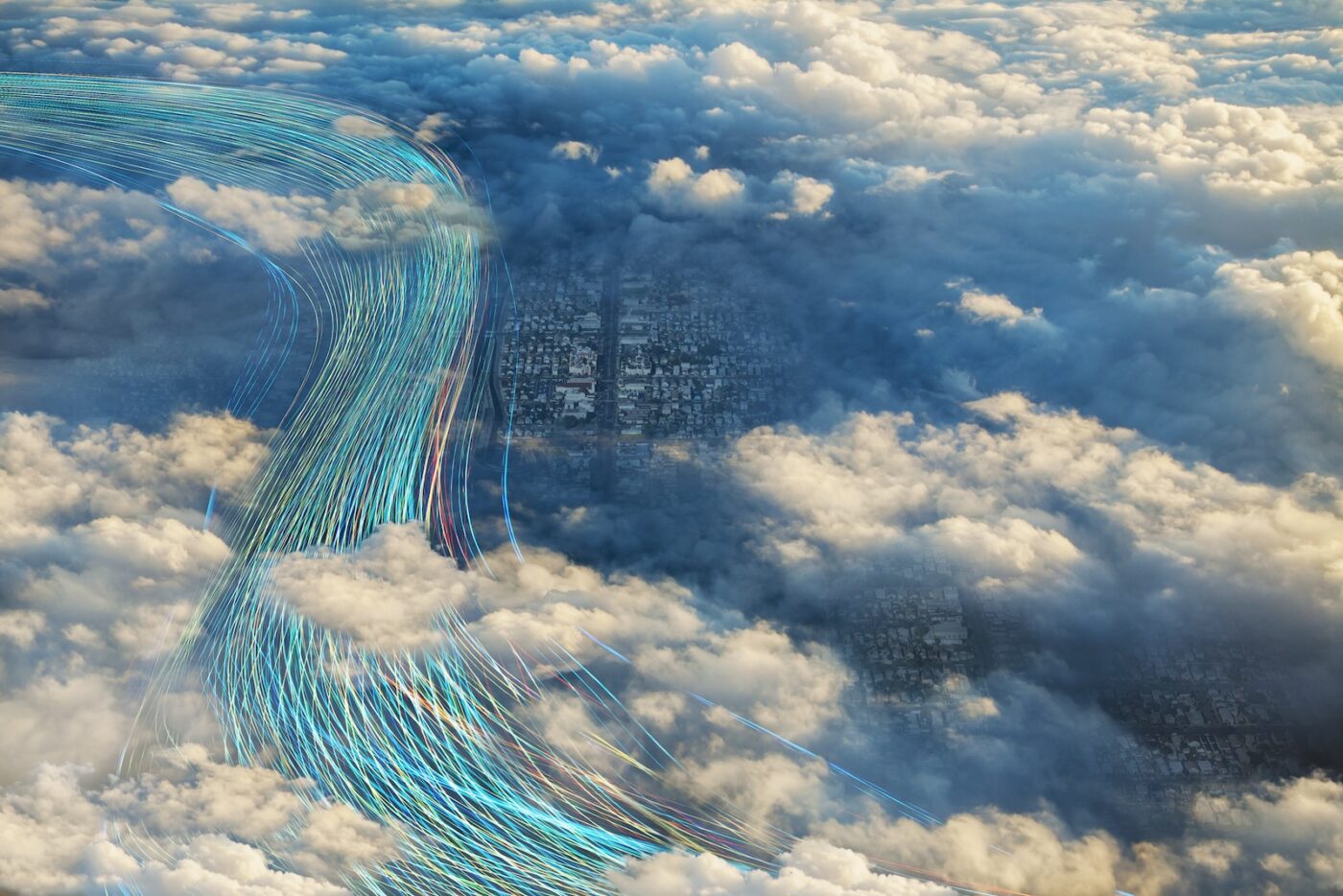

Industrial automation is undergoing a foundational shift. From industrial PC to edge gateways and smart sensors, compute needs at the edge are changing fast. AI is moving out of the cloud and into real-world environments. Systems once designed around predictable, single-purpose workloads must now run intelligent, updateable, and secure applications in dynamic, high-mix settings.

Traditional compute architectures, long optimized for high-volume, low-variation tasks, weren’t built for this. And as industrial OEMs push for greater flexibility, scalability, and AI-readiness, the Arm architecture – built around AI acceleration, power efficiency, real-time performance, and software portability – is gaining ground.

Why edge AI is redefining industrial compute

The fourth industrial revolution isn’t theoretical anymore. AI and machine learning (ML) are increasingly embedded across the industrial edge — guiding robots, managing predictive maintenance, optimizing energy use, and more. However, industrial edge AI introduces for core compute requirements:

- AI inference at the edge, close to sensors and actuators;

- Real-time responsiveness for control and safety;

- Low power usage in thermally constrained environments; and

- Secure, software-defined platforms that are easy to update and deploy.

For many OEMs, these challenges aren’t on the horizon; they’re blockers now. Today’s high-mix manufacturing environments are pushing conventional compute architectures to their limits, with three key challenges that are hindering innovation at the edge:

- Power inefficiency, which restricts innovations around form factor and thermal designs;

- Limited AI acceleration scalability across diverse workload profiles; and

- Rigid hardware-software integration, which slows innovation at the edge.

This requires compute platforms that are more adaptable, power-efficient, and scalable, hallmarks of Arm-based systems.

Why industrial OEMs are migrating to Arm

The move to Arm-based compute platforms in industrial settings at the edge is being accelerated by the following critical drivers:

- Built-in AI acceleration to support AI models running at the edge, enabling real-time decision-making in latency-sensitive environments.

- Performance-per-watt leadership to support compute-intensive tasks without blowing power budgets, allowing for more compact and thermally efficient designs.

- Platform scalability from microcontrollers to server-class processors on a common architecture, simplifying development across product lines and reducing time to market.

- Edge-to-cloud software portability, enabling developers to train in the cloud and deploy at the edge seamlessly – minimizing code rewrites and speeding up deployment cycles.

- A diverse silicon ecosystem, offering faster innovation cycles and fit-for-purpose design options across automation robotics, and industrial control systems.

- Long-term software and hardware roadmap alignment, giving OEMs confidence in lifecycle support and the ability to standardize on a future-proof architecture.

The latest Armv9 architecture brings these capabilities together, from the smallest Arm Cortex-A320 CPU cores for edge AI applications to the latest Arm Neoverse cloud cores, with adoption by leading industrial silicon vendors and built-in AI acceleration instructions. This architectural consistency streamlines development, reduces maintenance complexity, and enables faster innovation, especially as AI models become software updateable.

Arm’s platform approach, combining flexible compute IP, robust software tools, and a vibrant ecosystem, is helping OEMs reduce development friction while unlocking higher levels of integration, intelligence, and control at the edge. Industrial OEMs, like Siemens, are already embracing the shift.

“Siemens is committed to unlocking the power of AI in edge applications. The Armv9-based edge AI platform will help to extend our portfolio of highly secure, performant, and energy-efficient AI innovation.” Herbert Taucher, Head of Research and Pre-Development for IC and Electronics, Siemens AG

Listen to the conversation between Arm’s Paul Williamson and VDC Research’s Chris Rommel as they unpack how edge AI is transforming embedded systems and IoT development – covering everything from the rise of Python and Linux to the role of Arm’s ecosystem in enabling intelligent, scalable solutions.

How industrial systems are being designed for AI at the edge

For developers and product leaders, the shift to Arm means more than just swapping CPUs. It opens new pathways for design through the following ways:

- Heterogeneous compute architectures covering CPU, GPU and NPU to support embedded AI more efficiently.

- Software-updateable intelligence where AI models can evolve without hardware redesign.

- New form factors — fanless, rugged, or compact — enabled by thermal and power efficiencies.

- Modern DevOps workflows supported by containerization and cloud-native ML tools.

With one architectural foundation from edge to cloud, developers gain flexibility, faster iteration, and reduced friction across product lifecycles. One great example is Schneider Electric’s proof-of-concept built on Arm SystemReady, demonstrating how standardized Arm platforms simplify deployment and accelerate industrial innovation.

Why the future of industrial compute is edge-native

As more intelligence moves outside the data center, compute architectures must evolve. The next generation of industrial systems won’t be defined by legacy constraints, but by application needs: AI-readiness, flexibility, and real-time performance at the edge.

The broader trend is clear: industrial compute is becoming edge-native, and increasingly, Arm-native. To learn more about how Arm is revolutionizing AI at the edge to transform industrial infrastructure, visit Arm Edge AI.

Frequently asked questions

Q: What is edge AI in industrial automation?

A: Edge AI refers to running AI inference locally on industrial PCs, gateways, and sensors to enable real-time control, lower latency, and improved reliability without relying on cloud connectivity.

Q: Why are industrial OEMs adopting Arm for edge AI?

A: The Arm compute platform offer superior performance-per-watt, scalable AI acceleration, real-time capabilities, and long-term software portability across product families.

Q: Can industrial AI systems be update after deployment?

A: Yes, software-defined, Arm-powered platforms enable AI models and applications to be updated over time without changing the hardware design.

Q: How does Arm support edge-to-cloud development?

A: Arm enables developers to train AI models in the cloud and deploy them consistently at the edge using a common architecture and portable software stack.

Any re-use permitted for informational and non-commercial or personal use only.