Virtual Platforms from Arm and Partners Available Now to Accelerate and Transform Automotive Development

The automotive industry is currently at an inflection point being driven by a significant rise in the adoption of technologies and software in the vehicle, with this leading to what’s commonly referred to as the software-defined vehicle (SDV).

Alongside the exponential growth of software and advances in AI with a billion lines of code expected in next-generation SDVs, there are further additional complexities for the industry to navigate, including advancing electrification, increasing levels of automation and a new in-vehicle digital experience. This is requiring automotive manufacturers to re-think the electrical/electronic (E/E) architecture, which is leading to increasing levels of consolidation that need advanced levels of performance, safety and security. Against the backdrop of more complex computing demands are supply chain challenges, with the automotive industry looking to streamline the development and deployment of silicon and software in vehicles for a quicker time to market.

Addressing these broad challenges requires a new approach that delivers new hardware and immediate software enablement from day one. Arm is delivering next-generation leading-edge processors for our automotive partners through expanding the Arm Automotive Enhanced (AE) IP portfolio. However, a vital component in supporting our partners as part of the next step to develop and deploy silicon and software is new virtual platforms based on the new Arm AE IP that are available now.

Why are automotive virtual platforms essential for driving innovation and efficiency in the automotive industry?

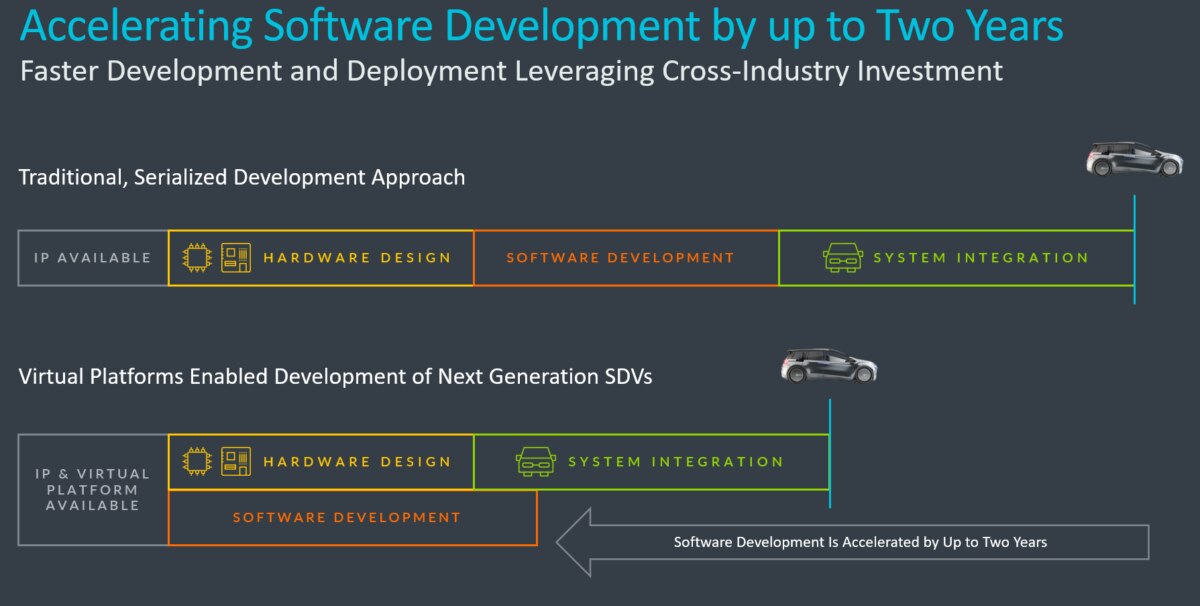

Virtual platforms allow our automotive partners to evaluate our IP before it is realized in silicon through virtual prototyping. This transforms the design process for partners who do not need to wait for the physical silicon to be in production, accelerating the development and deployment of silicon and software in SDVs for a far quicker time to market. This is important because enabling this development early is critical for the automotive industry to keep pace with the exponential growth in software. We predict that utilizing virtual platforms and the full-stack software solutions from our partners alongside the latest generation of Arm AE IP will save the automotive industry significant time and costs, accelerating development cycles by up to two years.

What are the three key use cases for automotive virtual platforms?

Built for specific AI-powered vehicle functions including advanced driving assistance systems (ADAS), in-vehicle infotainment (IVI) and digital cockpit, the virtual platforms target three key use cases during the system-on-chip (SoC) design and software development process:

- SoC architecture exploration, which helps our automotive partners developing silicon to explore their chosen SoC architecture in more detail through virtual prototyping.

- Firmware, real-time operating system (RTOS) and device drivers for base software platform development and integration. This includes OS porting and driver and middleware development.

- Function/ application development and unit testing, which supports software application development and validation.

Which automotive virtual platforms are currently offered by Arm and partners?

Even though, in most cases, the new Arm AE IP will be first available on silicon through physical development boards in 2025/26, the immediate availability of virtual platforms allows our automotive partners to start their virtual prototyping from day one. This means they can evaluate their design choices early ahead of the physical silicon being available.

Through Arm Fast Models, we create models of the Arm AE IP and then license these to our EDA partners who build tools that can be licensed to automotive partners. This largely focuses on base software platform development and integration.

Arm’s EDA and Cloud design partners have also released their own virtual platforms targeting all three use cases outlined previously. Siemens EDA is adding accelerated pre-silicon development in the cloud to its hardware assisted verification product offering with PAVE360 software for SDVs. The solution is the first accelerated simulation environment to support the new Arm Cortex-A720AE CPU. Corellium has its own modelling technology that runs on AWS Graviton in the cloud to deliver functionally representative virtual prototypes of the IP, but at very high levels of performance required for advanced AI workloads and the move towards E/E consolidation. Both virtual platforms deliver accelerated models of Arm IP running in the cloud for highly efficient software development and validation experiences. Cadence is also partnering with Arm to deliver a reference design and software development platform based on its Helium Virtual and Hybrid Studio to accelerate the development of chiplets for ADAS applications. There will be more virtual platforms from our partners available throughout 2024, so stay tuned for further announcements. You can read more about what our virtual platform partners have to say here.

How is ISA parity being achieved between cloud and edge?

The virtual platforms are designed to help bring ISA parity, otherwise known as “environmental parity”, between the cloud and edge. This is when exactly the same, or near identical, instruction-set architecture (ISA) is used in the cloud and at the edge (in the vehicle). Arm’s success in the cloud through our Neoverse platform combined with the adoption of the new Arm AE IP in vehicles means there is ISA parity between cloud and edge, with both being built on the Armv9-A architecture.

Looking at PAVE360 as an example, the identical ISA exists in the vehicle through the virtual prototype of Cortex-A720AE and also in the cloud through the AWS Arm Neoverse-based Graviton. This means automotive applications can be developed in the cloud and then seamlessly deployed at the edge for more efficient, far quicker automotive software development. Also, as long as the interfaces behave the same, the same binaries are available in the cloud and at the edge. While this is dependent on the differences between the virtual prototypes and the vehicle, this could mean that there is no need to recompile binaries or re-do the validation during the automotive development process.

This accelerates overall quality control and functional safety certification. Siemens EDA is already working closely with Arm and AWS to bring PAVE360 to the cloud for the frictionless evaluation of the Arm AE IP virtual prototypes.

How does cloud to edge deployment transform software development?

New cloud to edge development approaches – enabled by this ISA parity and the virtual platforms – are designed to transform the traditional embedded software development mindset. This change is needed because it is becoming clear that these current embedded software development methodologies will not keep pace with the growth in software complexity, especially considering the widening gap between levels of software complexity and productivity. A McKinsey study notes that as there has been a 5.5x increase in software complexity, there has only been an around 1.2x increase in productivity based on an analysis of more than 200 automotive projects.

Learn how incorporating virtual platforms can accelerate your time-to-market with this customized, interactive manual.

Click to read The Automaker’s Glovebox ManualCloud to edge development approaches mean software can be developed in the cloud and integrated with CI/CD workflows for continuous build, test and validation. This also leverages the benefits of running multiple high-performance workloads in parallel, streamlining the automotive development process, improving software productivity and improving multi-threaded workloads across heterogeneous compute domains commonly seen in modern automotive safety-based architectures.

How do Arm’s four pillars drive the delivery of SDVs?

The development of virtual platforms is a vital part of Arm’s four pillars geared towards delivering SDVs – industry collaboration, standards, modern methodologies and vehicle simulation. Thanks to SOAFEE and a standards-based approach, we have software ecosystem partners enabling full stack solutions on the virtual platforms on day one. SOAFEE plays an important role bringing together leading companies from across the automotive industry and software community, enabling hardware and software decoupling, and developing new software methodologies to deliver capabilities, such as mixed critical orchestration. Meanwhile, through open standards that enable workload portability, such as SystemReady and PSA Certified, Arm continues to drive the implementation of robust standards throughout the automotive industry. All of this provides a comprehensive package of support for Arm’s automotive and software ecosystem towards the development and deployment of computing solutions in SDVs.

How does the “shift left” in automotive development transform time-to-market challenges?

The new virtual platforms have a significant role in this broader “shift left” of automotive development and deployment that is designed to significantly reduce time to market and solve industry computing and supply chain challenges. Working with our EDA and cloud design partners, we are delivering virtual platforms that will accelerate this development and deployment process and enable a frictionless automotive development process from cloud to edge.

The end result will be automotive compute platforms that deliver unrivalled performance, efficiency and scale and enable faster software development and continuous updates over the lifetime of the vehicle. Our message to automotive partners is to dive into the new virtual platforms now and see how these technologies can benefit software and SoC developers and the broader automotive ecosystem. This will accelerate the journey to SDVs and deliver a more immersive, seamless and smoother driving experience.

Visit Arm at Embedded World to see the first automotive virtual platforms in action.

Arm in automotive markets

Arm and our world-leading partner ecosystem provide OEMs and the automotive industry with the processor IP, tools, and software solutions for automated driving, software-defined vehicles, and unique in-vehicle experiences.

Any re-use permitted for informational and non-commercial or personal use only.