How Arm-Powered Humanoid Robots Are Taking on the World’s Most Dangerous Jobs

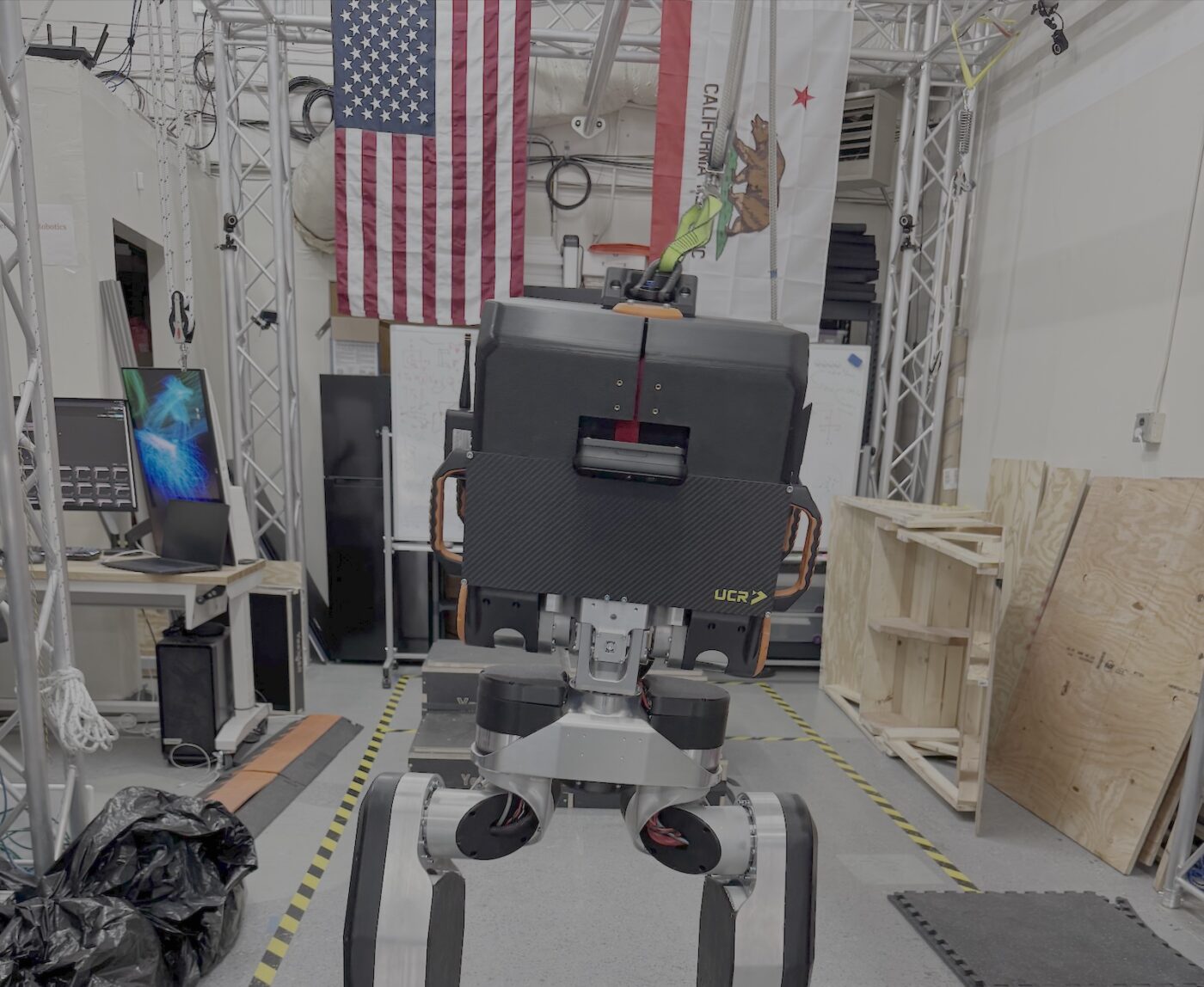

It was a moment of quiet tension in the Under Control Robotics (UCR) lab, in a small garage among a bay of innovators’ garages in the heart of Silicon Valley. Moby, the company’s first humanoid robot for hazardous environments, stood lifeless. Yet it seemed to stare intently at the challenge it faced: walking over a pile of debris, up a steep wooden ramp and down the other side—without falling. With no arms to assist in balance, Moby had to rely entirely on its advanced AI and lightweight IMU sensors. It took its first step. Then more. As it reached the top, it didn’t pause but immediately began its descent, and the robot smoothly made its way down. A triumphant moment. To test its stability, the engineers playfully shoved Moby from different angles, watching it absorb the force without tumbling.

It was more than just a cool demonstration—it was proof that UCR was onto something groundbreaking and maybe life-saving.

UCR’s Vision: Building Affordable Humanoid Robots for Hazardous Environments

Founded by a team of robotics veterans in the spring of 2024, UCR wants to solve a critical problem: the lack of scalable, multipurpose humanoid robots that can handle dangerous and labor-intensive tasks. Unlike high-cost, highly specialized robots that dominate industries like manufacturing, UCR’s focus is on making humanoid robots affordable and adaptable for sectors like construction, mining, and energy.

Co-founder Wei Ding and his team bring decades of experience from NASA’s Valkyrie project, autonomous system development at Apple, and humanoid research at Caltech. They envision humanoid robots that can navigate rough terrain, monitor industrial sites, and assist with material handling—all without needing the heavy, power-intensive computation to solve complex math and dynamics problems in real time, which has traditionally held robotics back.

Before co-founding UCR, Wei Ding spent nearly seven years at Apple working on autonomous systems, specializing in motion planning, decision-making, and machine learning. CTO Wenlong Ma developed the first running humanoid robot in the world when he was pursuing his Ph.D. at Caltech. Head of Hardware Chris McQuin is famous for being the chief engineer of Valkyrie. Wenda Wang, head of AI, led the perception system of Apple autonomous systems as a staff machine learning engineer.

Redefining Edge AI Efficiency with Arm-Powered Humanoid Robotics

One of UCR’s key breakthroughs is its lightweight AI model. Instead of requiring powerful onboard computers to constantly process complex physics equations, the team trained its models in simulated environments. Once optimized, the AI runs on NVIDIA’s robotics-optimized Jetson Orin platform using Arm Cortex-A78-class processors, making it far more power-efficient and cost-effective than traditional edge AI robotics. The robot also uses a number of motor controllers, packaged into actuator modules using Arm-powered STM32 processors.

“Arm was the clear choice for us because it offers the best combination of energy efficiency, cost-effectiveness, and performance for edge computing,” Ding said. “Our AI model runs efficiently on a single Arm CPU core with minimal power draw, something that would be much harder to achieve on x86. Plus, Arm’s architecture is actually three to four times faster in certain key computations, like matrix vectorization, which is critical for real-time robotics. As we scale, the integration with NVIDIA’s Jetson platform gives us access to powerful AI acceleration while keeping our system lightweight and power-efficient.”

The prototype is able to walk entirely using an inexpensive IMU sensor, the same type of sensor found in smartphones to detect orientation. Their new generation of AI model integrates vision capabilities, which gives the robot the ability to perceive and adapt to its surroundings more effectively.

Moby’s first field trip

Why Hazardous Jobs Are Ideal for Industrial Humanoid Robots

UCR isn’t trying to replace human workers in warehouses or retail—industries where a robot for mining, construction, and hazardous energy sites, makes a critical difference. Instead, the company is targeting environments where humans face serious risks, such as offshore oil rigs, hazardous construction sites, and deep mining operations.

“In mining or offshore operations, safety is paramount,” Ding said. “Sending a human into a dangerous environment requires extensive preparation, PPE, and often leads to operational downtime. But a robot? It doesn’t need oxygen. It doesn’t inhale toxic fumes. It can be deployed immediately.”

This approach not only protects human lives but also offers massive cost savings to industries that measure downtime in millions of dollars per hour.

The Road Ahead: Scalable Humanoid Robot Prototype in 4 Months

UCR is moving quickly. With just four team members, they designed and built their first full-sized walking humanoid robot in just four months—one of the fastest development speeds witnessed by the industry, they claim. By the end of March, the team plans to integrate arms into the design, enabling the robot to manipulate objects and perform more complex tasks.

As robotics continues to advance, UCR’s work signals a shift toward scalable, cost-effective humanoid systems that can tackle the world’s toughest jobs. And if Moby’s ramp-walking debut is any indication, this is just the beginning.

“As robotics shifts toward edge computing, Arm is quickly becoming the default choice,” Ding said. “It’s not just about power efficiency; Arm’s architecture is fundamentally better suited for real-time, AI-driven robotics. The ability to run complex models on a low-power system without sacrificing performance is a game changer. For mobile humanoid robots like ours, where every watt counts, Arm is the future.”

Any re-use permitted for informational and non-commercial or personal use only.