How Predictive Maintenance Saves Time, Costs and Downtime in Smart Factories

When a critical pump grinds to a halt, a wire snaps mid-shift, or a component quietly wears out, production doesn’t just pause, it costs. In smart factories, these unplanned equipment failures can stall entire operations and drain millions of dollars. Predictive maintenance flips the script, using AI and real-time sensor data to spot trouble before it strikes—cutting downtime, slashing maintenance costs, and keeping machines running at peak performance.

What’s the Cost of Unplanned Downtime?

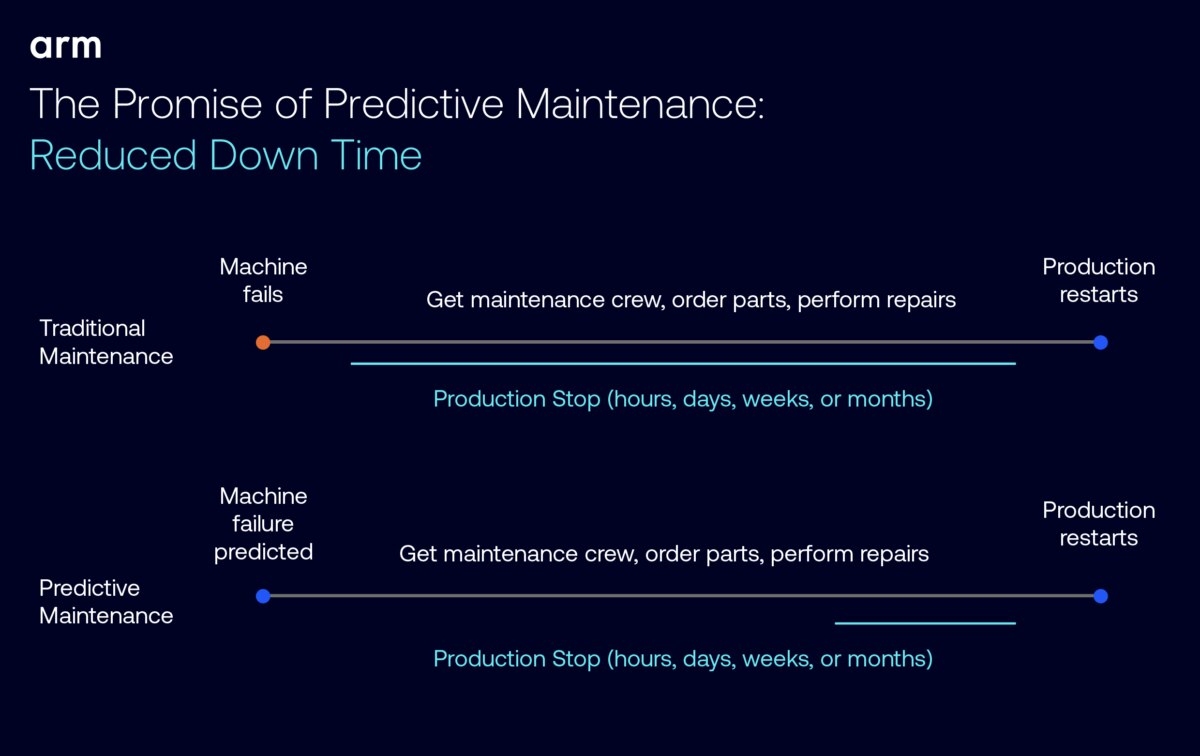

In the manufacturing sector, unexpected equipment failures can result in substantial financial setbacks. A 2024 Siemens report estimated that unplanned downtime costs the world’s 500 biggest companies up to $1.4 trillion annually. Traditional maintenance strategies, such as reactive repairs or scheduled servicing, often fall short in preventing these disruptions.

How Does Predictive Maintenance Solve the Problem?

Predictive maintenance utilizes AI and machine learning algorithms to analyze data from sensors embedded in machinery. By monitoring variables like vibration, temperature, and pressure, these systems can identify patterns indicative of potential failures. This approach allows for maintenance to be scheduled just in time, reducing unnecessary servicing and preventing unexpected breakdowns.

What’s Neuton.AI’s TinyML Approach to Predictive Maintenance?

Neuton.AI, an Arm partner, exemplifies the practical implementation of predictive maintenance in smart factories. Their no-code TinyML platform enables the development of compact, efficient machine learning models that can run on microcontrollers with limited resources. These models can process sensor data in real-time, facilitating immediate detection of anomalies and potential failures.

For instance, Neuton.AI has demonstrated the use of their platform in monitoring compressor water pumps. By analyzing sensor data, the system can predict when a pump is likely to fail, allowing for timely maintenance and avoiding costly downtime.

What Are the Benefits of Predictive Maintenance?

- Reduced Downtime: By predicting failures before they happen, maintenance can be scheduled proactively, minimizing unplanned downtime.

- Cost Savings: Targeted maintenance reduces unnecessary servicing and extends equipment lifespan, leading to significant cost reductions.

- Improved Safety: Early detection of potential failures helps prevent accidents, ensuring a safer working environment.

- Enhanced Efficiency: Real-time monitoring and maintenance scheduling optimize production processes, increasing overall efficiency.

How Can You Implement Predictive Maintenance in Your Facility?

Adopting predictive maintenance involves integrating AI and sensor technologies into existing systems. Platforms like Neuton.AI’s TinyML offer accessible solutions that don’t require extensive coding knowledge, making it feasible for facilities of various sizes to implement. By starting with critical equipment and gradually expanding, manufacturers can transition to a more proactive maintenance strategy.

What’s the Future of Smart Manufacturing Look Like?

As smart factories continue to evolve, predictive maintenance will play a crucial role in ensuring operational efficiency and competitiveness. The integration of AI and machine learning into maintenance strategies not only prevents costly downtime but also paves the way for fully autonomous maintenance systems. Embracing these technologies today sets the foundation for tomorrow’s smart factories.

How Does Arm Power Predictive Maintenance at the Edge?

Arm’s energy-efficient, high-performance processors are central to enabling predictive maintenance at the edge. With support for TinyML models and real-time data processing, Arm-based microcontrollers and NPUs—like those used in Neuton.AI’s solutions—empower smart factories to analyze sensor data on-device. This approach reduces latency, lowers cloud dependency, and enhances reliability, making predictive maintenance not only faster but also more scalable and cost-effective.

Key Takeaways

- Predictive maintenance reduces costly downtime by detecting potential equipment failures before they happen, using AI and real-time sensor data.

- Arm-based microcontrollers enable edge intelligence, running TinyML models directly on devices for fast, reliable, and low-power anomaly detection.

- Neuton.AI’s no-code platform simplifies deployment, allowing manufacturers to implement predictive maintenance on resource-constrained hardware without deep ML expertise.

Frequently Asked Questions

What is predictive maintenance, and why does it matter?

Predictive maintenance uses AI to analyze sensor data and detect early warning signs of equipment failure, minimizing downtime and repair costs.

How does Arm technology support edge-based predictive maintenance?

Arm processors provide the performance and energy efficiency needed to run TinyML models on microcontrollers, enabling real-time insights without relying on the cloud.

Who is Neuton.AI, and how do they contribute?

Neuton.AI is an Arm partner offering a no-code TinyML platform that empowers manufacturers to easily deploy predictive models on embedded systems.

Can small and mid-sized factories adopt this technology?

Yes. With platforms like Neuton.AI and Arm’s efficient hardware, predictive maintenance is accessible and scalable for operations of all size.

Unlock the Power of Edge AI in Real-World IoT

Explore how AI at the edge is reshaping industries—from real-time decision-making to smarter, more efficient operations.

Any re-use permitted for informational and non-commercial or personal use only.